Fusion’s Supply Chain Moment: HTS Magnets, Blankets and Balance-of-Plant

Nuclear fusion could one day power homes and businesses with clean energy.

Credit: UK Atomic Energy Authority

Keeping promises means building factories, not just physics

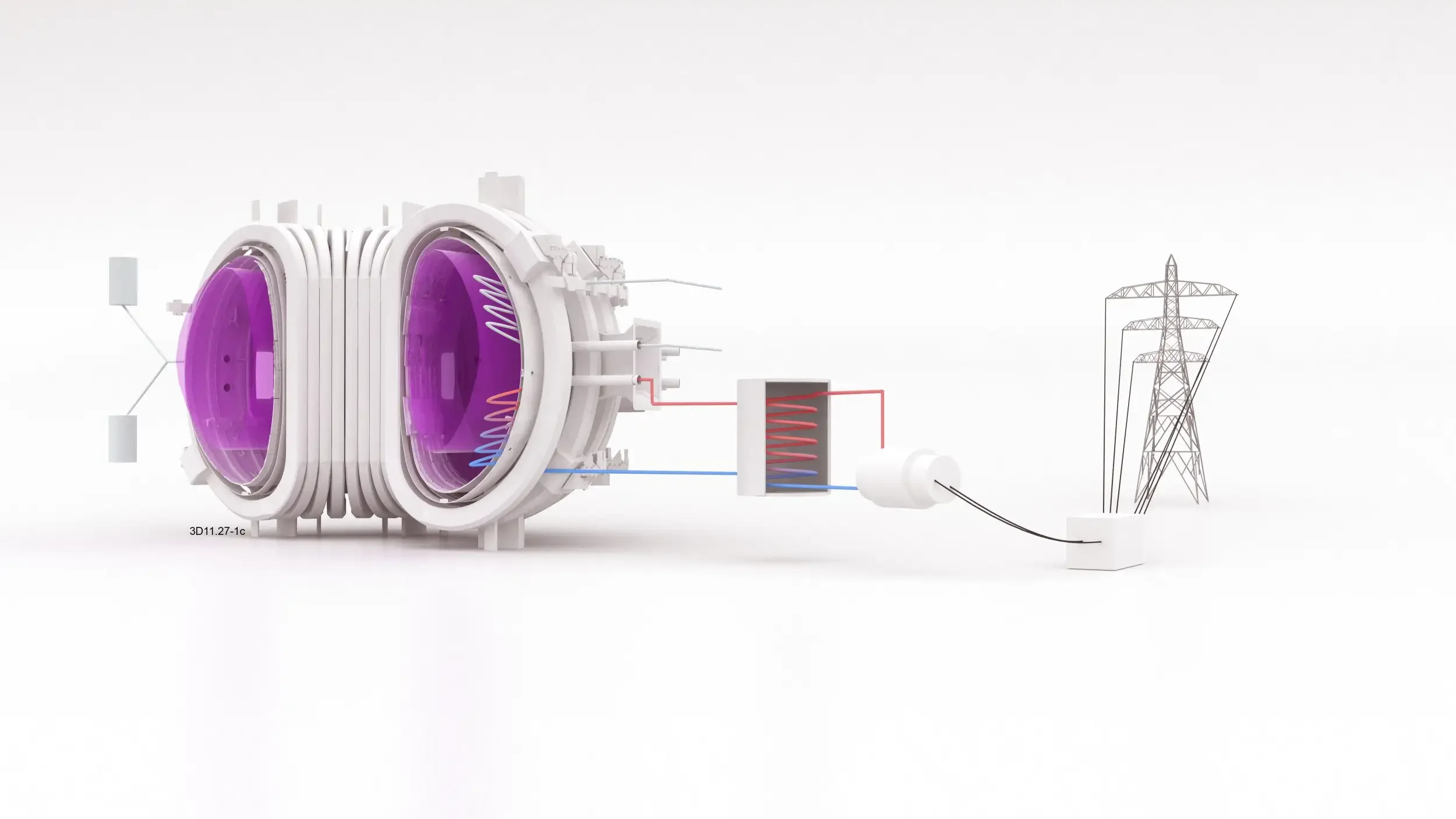

Every breakthrough machine eventually becomes a supply chain. Fusion is at that turn. The science headlines—record plasmas, repeatable ignition shots—have created a new bottleneck that isn’t solved in a control room: who will build the parts, at volume and with paperwork that financiers and regulators trust? Three subsystems tell the story: HTS magnets, breeding blankets, and the balance of plant that turns heat into megawatts. If those three industrialise, first-of-a-kind plants stop being architecture diagrams and start being projects.

Start with the magnets, because everything else literally wraps around them. HTS magnets use high-temperature superconducting tapes—typically REBCO, a ceramic film laminated onto metal—to carry huge currents with almost no electrical resistance. “High temperature” is relative: they still run cryogenic, but warmer than legacy niobium magnets, which makes the whole cryogenic system simpler and the magnets themselves smaller for the same magnetic field. Smaller, stronger magnets mean a more compact machine, less civil engineering and shorter assembly schedules. The business catch is familiar: tape manufacturing has lived in pilot lines and niche markets; fusion needs kilometre-scale runs with consistent performance and defect rates, delivered on a calendar, not on hope. Buyers will ask the same questions turbine makers answered years ago: what’s your yield, what’s your lot-to-lot variation, and what’s the requalification plan when the process drifts?

Inside the vacuum vessel lives the least glamorous, most essential subsystem you’ve barely heard of: the breeding blanket. Fusion reactors using deuterium and tritium must make their own tritium; the blanket does that by surrounding the plasma with materials that, when hit by fusion neutrons, breed tritium from lithium. Two ideas dominate: liquid metals (lead–lithium) moving through channels, or ceramic pebble beds—millimetre-scale lithium-bearing pellets that flow heat to coolant circuits while breeding tritium. Whichever path a project chooses, the commercial questions rhyme. Can you fabricate blanket modules to tight tolerances, weld and test miles of cooling channels, and prove you can extract and account for every gram of tritium safely? “Tritium handling” may sound exotic; in business terms it’s custody, metering and loss accounting—disciplines energy companies already understand, now applied to a radioactive isotope rather than gas or liquids.

Everything beyond the vessel is the balance of plant (BoP)—the industrial kit that takes heat and makes electricity: heat exchangers, pumps, valves, steam cycles, cooling towers, power electronics. This is where fusion leans on mature suppliers from conventional power. The trick is integration. Fusion heat can be pulsed; some concepts want supercritical CO₂ turbines rather than classic steam; materials will see neutron damage that accelerates ageing. None of that is unsolved, but it demands BoP vendors who are comfortable with first articles, extended factory acceptance tests, and spares pools that recognise FOAK realities.

How does this translate into a credible plan rather than a wish list? Treat each subsystem as a programme with its own cash register and risk book.

Magnets need a dual track: lock long-lead buys for HTS tape early—hedging price and securing allocation—while qualifying at least one alternate vendor to avoid single-point failure. Build magnet modules on a takt, not as one-off art pieces; publish yield and rework statistics so lenders see learning curves, not surprises. For field assembly, invest in jigs and transport fixtures that cut handling risk; a dropped coil is months, not days.

Blankets live or die on manufacturing discipline. Move quickly from single test coupons to full-height mock-ups with realistic welds, bends and inspection ports. Set up non-destructive evaluation that catches porosity or micro-cracks before modules are sealed. On tritium, treat the extraction system like a regulated treasury function: reconciliation by lot, alarm thresholds for losses, and a clear path to safe storage and resale. If you can show an auditor that mass balance works on week one of hot commissioning, you will save yourself months later.

BoP is where fusion borrows bankability. Choose interfaces that keep most of the plant inside existing standards—pipe specs, pump curves, pressure-vessel codes—so only a narrow slice is truly novel. If you want a supercritical CO₂ cycle, carry a steam fallback through conceptual design long enough to price the option; that flexibility often unlocks cheaper financing or better EPC interest. And be honest about the grid. If your plant will ramp to support renewables, write that into the turbine and power electronics specifications; you cannot add “flexible” later with a paragraph.

Across all three subsystems, the commercial levers are boring on purpose: long-lead procurement, qualification, documentation and contracts. Long-lead items—HTS tape, specialty steels, large forgings, cryo hardware—need deposits early and frame agreements that scale. Qualification should look like an airworthiness plan: define the tests, acceptance criteria and requalification triggers up front. Documentation is not a chore; it is the asset that lets you build the second plant faster and finance it cheaper. And contracts matter: use availability-based elements and milestone payments tied to tangible artefacts, not just progress reports.

The people part is just as real as the parts. A fusion factory is a blend of superconducting specialists, nuclear-grade fabricators and rotating-equipment veterans who haven’t shared a shop floor before. That argues for co-location where it speeds learning—magnet winding near cryo assembly, blanket fabrication near high-energy NDE—and for supplier development that looks more like automotive than research: vendor scorecards, corrective actions, second sourcing. Localisation will be a political pressure; treat it as a sequencing problem. Build the first units where capability already exists; transfer work once procedures are frozen and staff can be trained against finished playbooks, not grey literature.

All of this adds up to a simple test: can a project manager show, with a straight face, that the critical path is governed by production rather than by “we’ll see in physics”? If yes, the conversation moves from magazines to money. Utilities and data-centre buyers don’t need to be convinced that firm, zero-carbon power is valuable; they need to be convinced your plant connects when you say it will and stays online when you promise. That is why the supply chain is the story. Magnets that arrive on cadence, blankets that breed and don’t leak, BoP that behaves like an industrial plant—those are the milestones that retire risk and justify a contract.

Fusion has spent decades in the future tense. The tense now is present continuous: building magnets, welding blankets, booking turbines. The winners won’t be the loudest physics claims; they’ll be the teams that industrialise these three subsystems, prove repeatability, and let financiers price the risk. Do that, and the grid will happily take the electrons.