Habitat Manufacturing: Printing Specialised Structures for Orbit, Moon, and Mars

ESA’s concept of a 3D-printed lunar base with a dome designed by architects Foster + Partners.

Credit: ESA/Foster + Partners

Modular shells, local materials, and factory-style assembly in space or non-terrestrial land

Habitats must be strong, pressurised, and reconfigurable—three requirements tailor-made for additive manufacturing. On-orbit fabrication can produce micrometeoroid shields, pressure shells, docking rings, and truss-work sized beyond fairings. Off-world, local-material printing (e.g., regolith-based composites) enables landing pads, berms, and later, living volumes that would be prohibitive to launch from Earth.

The commercial advantage is modularity: treat habitats as kits of parts with standard interfaces. Operators expand capacity by adding printed segments and swapping purpose-built modules—labs this quarter, greenhouse next. Logistics simplify because raw materials and print tools are more mass-efficient than fully finished volumes.

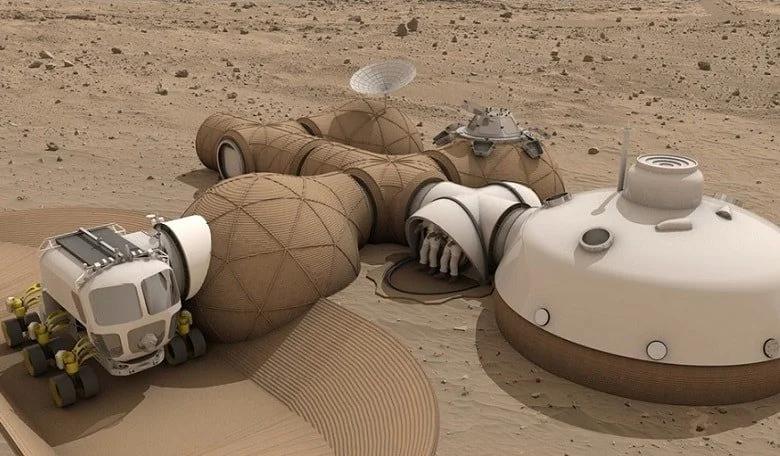

LavaHive’s 3D-printed sub-habitats are modular structures for Mars, built using available Martian raw materials.

Credit: LavaHive/NASA

Commercial takeaways

Market positioning centres on “habitat-in-a-kit” concepts: printed frames with standard interfaces that let operators add volume or swap modules as needs change. The buyer set spans station primes, sovereign users and defence-adjacent programmes planning phased build-outs. Contracts typically blend up-front design and certification with retained print capacity, maintenance and support. Routes to market run through station consortia, lander providers and life-support OEMs. Credibility is being built via full-scale ground mock-ups, destructive testing, and interoperability demonstrations that allow third-party modules to mate with printed structures.

Manufacturing habitats like software—versioned, modular, upgradable—turns living in space from an expedition into a product business.