Living on the Moon: Closed-Loop Life Support as a Product

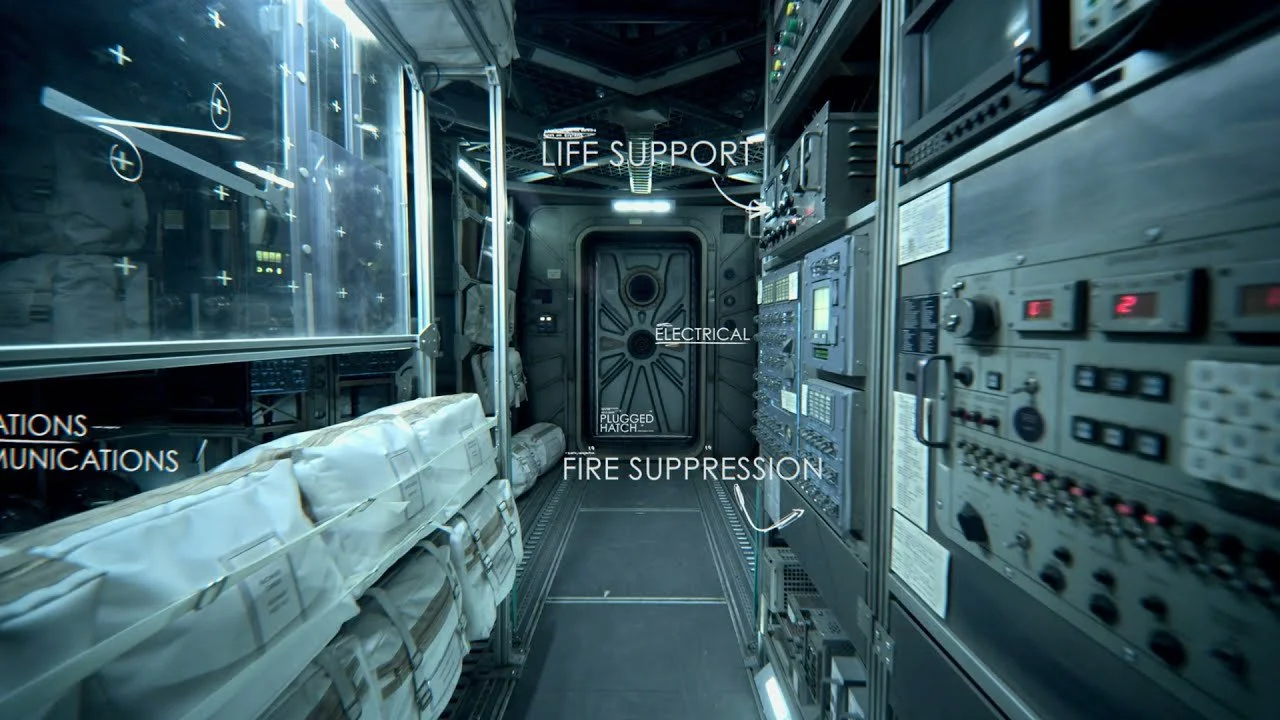

Interior of a lunar base from the "For All Mankind" Jamestown tour.

Credit: Apple TV+

Greenhouses, water loops, and medical capability for steady uptime

Crewed presence turns on one KPI: uptime. Environmental control and life support systems (ECLSS) close loops for air, water and waste; greenhouses and bioreactors shave resupply; medical capability turns serious incidents into survivable ones. Technically, it’s a ballet of filtration, catalysis, microbial control, redundancy and power budgeting. Commercially, it’s a service promise: keep the base within safe envelopes, hour after hour.

The productisation journey begins with modular subsystems tested in orbit—water processors, oxygen generation, CO₂ scrubbing—graduating to integrated surface stacks. The edge in this market isn’t a single invention; it’s an operating system that diagnoses itself, isolates faults, and guides crew through recovery procedures. Think of it as a safety franchise, complete with training, certification and remote monitoring.

Go-to-market communication is less about spec sheets and more about reliability narratives. Buyers—habitat developers, scientific stations, sovereign programmes—want continuity plans: how spares are managed, how upgrades roll in without downtime, how remote assist works when bandwidth is tight. Contracts read like availability agreements, not hardware invoices, and may include tiers tied to crew hours supported. Channels run through habitat primes and medical systems integrators; adoption happens in staged deployments where a single loop is entrusted first, then the full stack. Trust is the moat; once a provider proves steady-state life support under real conditions, switching becomes a risk few managers will take.