Space Elevators: From Lunar Pilots to GEO Freight

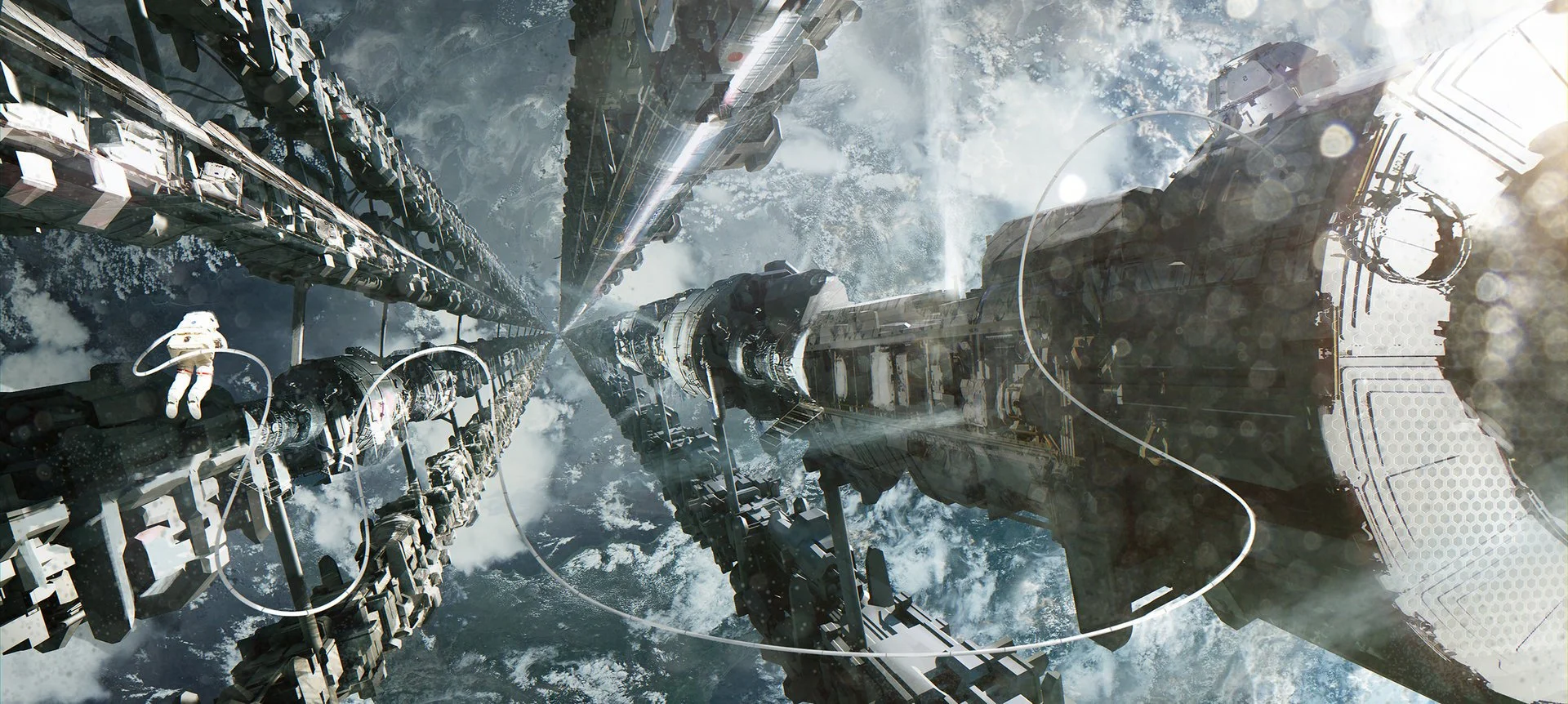

Futuristic space elevator infrastructure, with a tethered astronaut for scale (concept art).

Image credit: David Edwards on Artstation

Learning On The Moon, Then Building A Real Logistics Spine For Earth Orbit

If rockets set the pace of orbit for the last 60 years, elevators would change the economics entirely. Once a tether is up, mass flow is governed by electric power and climber throughput, not propellant. The realistic path is staged: prove operations on the Moon—where gravity and materials are on our side—then move toward an Earth-to-GEO system when tether materials and governance catch up. This piece lays out what’s actually buildable, how you’d finance and run it, and who wins if cadence replaces launch scarcity.

Design That Scales (Without The Sci-Fi)

An Earth or space elevator anchors near the equator and stretches past geostationary orbit (GEO) to a counterweight. Cargo rides electric climbers up the ribbon; momentum is balanced by traffic and counterweight management. The gating item isn’t software—it’s tether material with the strength-to-weight to hold its own mass plus safety margins over ~100,000 km. Early NASA Innovative Advanced Concepts (NIAC) work by Bradley Edwards defined the modern architecture but also made clear the material hurdle: lab-scale carbon-nanotube (CNT) strengths look fantastic; long-length, defect-controlled fiber supply does not yet meet the mark. That’s why Earth elevators remain pre-industrial.

A lunar elevator is the opposite story. Lower gravity and slower rotation mean today’s high-performance polymers (e.g., Zylon/Dyneema) can serve as the tether, enabling a surface-to-L1 “spaceline.” Multiple studies—including NIAC work led by J. Pearson and recent analyses in the Journal of the British Interplanetary Society—conclude a lunar elevator is feasible with existing materials, making it the sensible first build to learn deployment, repair, and traffic rules.

Build, Finance, Insure

A space elevator should be planned as regulated infrastructure, not a showpiece. Capital expenditure concentrates in four systems: the tether, anchor and port facilities, climbers, and inspection/repair robotics, assuming such technologies evolve in tandem. For an Earth installation, credible first-of-a-kind costs sit in the tens of billions; a lunar system is materially cheaper because suitable tether materials already exist and launch mass is far lower. Industrial roadmaps from firms such as Obayashi keep Earth concepts on the horizon (often in the 2050s), but even the optimists assume carbon-nanotube–class fibers must progress from laboratory results to reliable, long-length manufacturing before schedules become investable.

Operating economics are driven by electricity and maintenance, not propellant. The theoretical energy to lift one kilogram from Earth to GEO is about 50 megajoules (~15 kWh). Even allowing for conversion losses, unit cost trends toward power price + operations amortisation, establishing a structural floor well below today’s GEO launch pricing once the asset is mature. That is the central advantage: cost per kilogram falls as utilisation rises, a physics-based curve rather than a marketing claim.

Insurability improves when the asset is managed like a railway, with continuous monitoring and planned interventions. NIAC concepts treat the tether as a maintained line: distributed sensors for real-time health, climbing repair robots that patch micrometeoroid damage, and scheduled section replacements with documented quality control. Lenders and insurers respond to demonstrated availability and maintenance regimes, not renderings. Uptime, audit trails, and replaceable modules are what convert a visionary design into a financeable asset.

How You’d Operate It

On Earth, the port is a sea-based platform near the equator for weather and safety. Traffic rules prevent oscillations (climbers are sequenced so forces balance). Power can be transmitted to climbers (laser/microwave beaming) or onboard (batteries), with hybrids likely. On the Moon, operations are simpler: a surface anchor and a Lagrange-point hub with steady traffic moving regolith, water, and refined products off the surface. Pearson’s NIAC studies outline exactly that highway, turning cislunar space into a set of predictable routes rather than bespoke missions. The commercial impact should therefore take the near- and long-term consequences into consideration.

Near term (lunar): Cheap up-and-down for regolith, water ice, and metals, enabling surface refuelling, shielding, and in-space manufacturing at L1. That supports landers, depots, and persistent stations with lower logistics noise than rockets alone.

Medium term (Earth, GEO focus): High-cadence delivery of satellites, propellant, and bulk structure to GEO makes on-orbit servicing and assembly routine—tug fleets, life-extension, debris capture staged from the tether instead of bespoke launches. Operators can treat GEO like an industrial park with predictable replenishment, not a once-and-done destination. The International Academy of Astronautics (IAA) assessment frames this shift as an infrastructure play once materials and ops converge.

Long term: If you can move bulk mass to GEO cheaply, you can assemble solar-power satellites and very large platforms. Earthside, the prize is a throughput economy instead of launch rationing: prices gravitate toward electricity + amortisation, new categories (bulk materials, habitats) become viable, and entire supply chains—comms, earth-observation, manufacturing—pivot from “what fits a fairing” to “what fits the climber manifest.”

Winners, Pressures, And The Politics Of Building A Vertical Railroad

If an elevator becomes real infrastructure, the early economic winners are easy to spot. Equatorial port nations that host Earth anchors gain a new class of concession revenue, high-skill jobs, and geopolitical leverage—much as aviation hubs did in the jet age. Power utilities benefit too, selling firm capacity to climbers whose throughput is ultimately limited by electrons, not propellant. In orbit, GEO service firms—the companies that assemble, refuel, repair and de-orbit hardware—graduate from bespoke missions to steady, scheduled work. And on the ground, construction and materials leaders that can manufacture long-length tether segments with rigorous quality assurance become the gatekeepers of the entire value chain.

There are pressures as well. Heavy-lift launch to GEO loses some bulk-cargo demand as the elevator takes over routine mass flow; rockets refocus on low-Earth orbit, beyond-LEO exploration, time-critical deliveries and human transport—missions where speed, flexibility or certification favor propulsive flight. The materials industry faces the real bottleneck: the carbon-nanotube fiber gap. Lab results are impressive, but scaling to kilometer-grade, defect-controlled fibers with predictable yield is the missing link between papers and ports. Progress in composites and CNT fibers continues, yet the decisive step-change an Earth tether needs has not arrived.

Politically, the governance model is not a blank page; it is a fusion of familiar regimes. Licensing would look like undersea cables (international corridors and repair rights), airports (operational safety zones and traffic rules), and nuclear-grade quality (traceability, inspection, and liability). Expect international oversight on debris interaction and collision avoidance, clear liability frameworks, and “open-access” capacity rules so the tether functions as shared infrastructure rather than a private tollbooth. The playbook exists—we are applying it to a new vertical.

A Sane Timeline

Start on the Moon. A lunar elevator can be built with materials we already know how to manufacture, which makes it the right classroom for everything that turns a concept into infrastructure: deployment, inspection, repair, and traffic scheduling. It would also lay down a cargo spine for early lunar industry—moving regolith, water, and refined products between the surface and cislunar waypoints without the logistics noise of one-off launches.

In parallel, push Earth-side prerequisites up the learning curve. The true gate is not software or control theory; it’s fiber supply—raising carbon-nanotube (and related) composites from lab success to kilometer-scale, defect-controlled production with predictable yield. That demands investment in process engineering, metrology to spot and quantify defects, and pilot lines that prove repeatability. Dates should be set by demonstrated fiber performance at scale, not by optimistic extrapolations from short test coupons.

Finally, convert interest into execution through partnerships. Watch for civil engineering majors, such as Obayashi, and national programmes to move beyond concept pages into funded trials—materials runs, section fabrication, robotic inspection and repair—aligned to IAA/NIAC roadmaps. When those efforts come with milestones, budgets, and accountability, you’ll know the risk is being priced rather than waved away.

Conclusion: The Journey From Concept To Infrastructure Can Be Realistic

Space elevators shift from speculation to investable reality when they are treated as infrastructure with a learnable operating curve. The Moon is the rational starting point: suitable materials already exist, deployment and repair can be rehearsed at scale, and the logistics payoff—for moving regolith, water and manufactured goods between the surface and cislunar nodes—is immediate and measurable. Earth follows when tether fibers advance from laboratory coupons to factory-grade, kilometer-length production and when governance, liability and access rules are formalised.

The commercial implication is decisive. Freight to GEO becomes a function of electric power, availability and maintenance discipline, not propellant cost or launch-window scarcity. That flips the business from bespoke missions to throughput logistics with predictable unit economics and service-level commitments. At that point, capital can be priced against uptime, cadence and contracted volumes—the same variables that finance railways and subsea cables—rather than against optimism about the next launch.