Two Sites, One Goal: SpaceX’s Internal Rivalry and the Speed of Starship

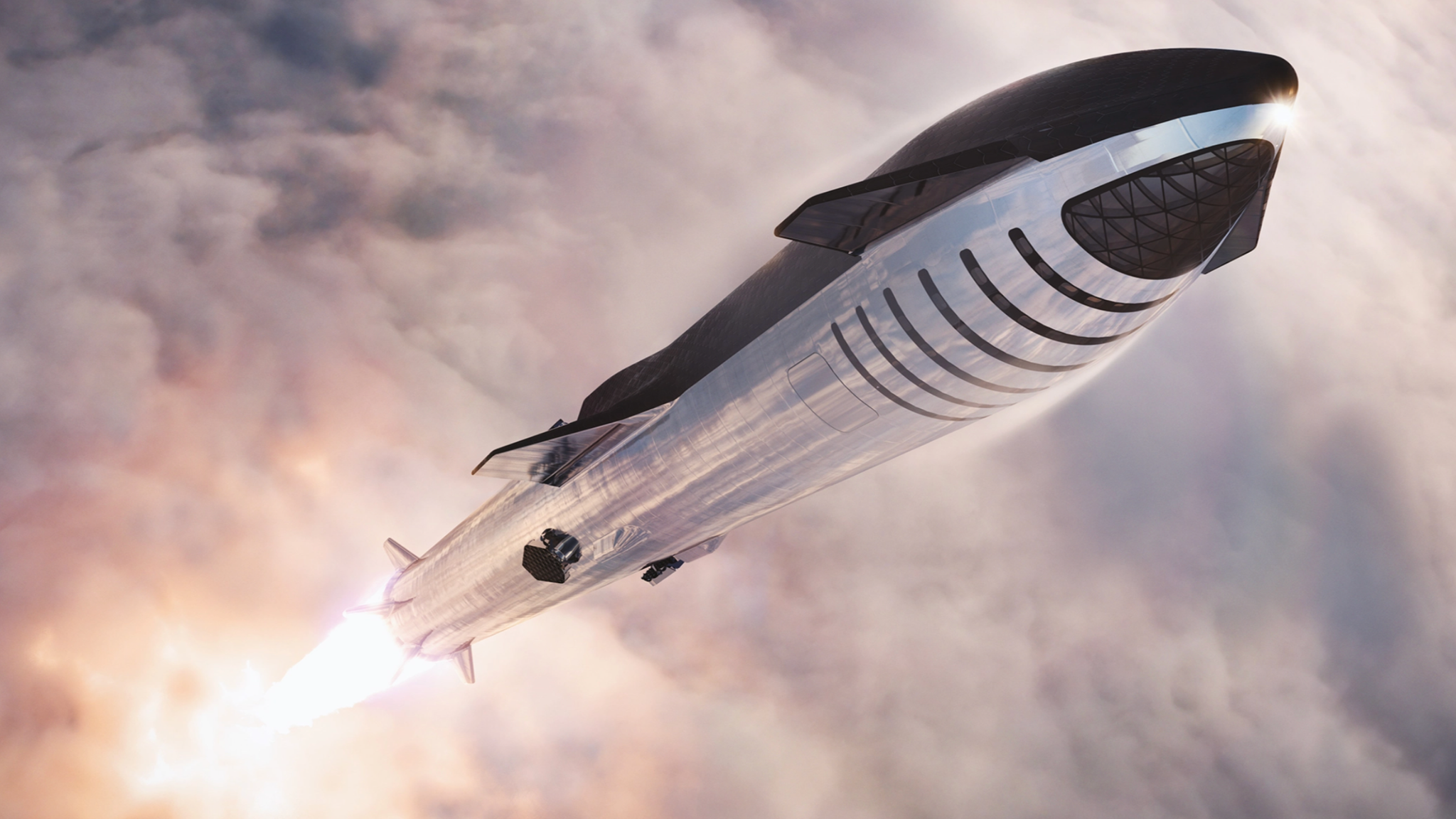

Concept art of Starship and the Super Heavy booster, the largest space rocket ever built, launching into space.

Credit: SpaceX

How orchestrated competition between Texas and Florida sharpened design, cadence and cost

When SpaceX began building the first Starship prototypes, Elon Musk didn’t bet on a single site or a single way of working. He ran simultaneous, competing builds—one in Boca Chica, Texas, and one on Florida’s Space Coast—and made the race itself part of the engineering method. He said so publicly: “simultaneous competing builds of Starship in Boca Chica, Texas & Cape Canaveral, Florida.” The company and outside reporters framed it as a friendly internal contest to see which team could move faster and learn more, with knowledge shared across both sites.

Musk also pitched it as a “super fun race to orbit, Moon & Mars,” adding a simple rule: let teams diverge, compare results quickly, then propagate the better approach. Contemporary coverage and on-the-record remarks captured that intent; analysis pieces noted that competition between the teams would likely improve the final Starship design by forcing parallel experiments in structures, welding, and build sequencing.

This is not just folklore; it shows up in research on NewSpace methods. In reviewing innovation through internal competition, SpaceX’s Starship programme is cited for using a Texas vs. Cape Canaveral race to drive speed and learning—compared with agile “sprints” in software that pit approaches against one another, then fold successful patterns back into the mainline. The effect isn’t duplication for its own sake; it’s shorter learning loops and fewer architectural blind spots when the stakes are high.

Commercially, the value of this approach is straightforward. Parallel prototyping uncovers manufacturability snags faster, lifts first-time-right rates on later builds, and narrows unit-cost uncertainty before committing to volume tooling. SpaceX spoke about design and manufacturing improving “exponentially” as a result of the contest, and later flight campaigns have shown the cadence benefits of that learning culture. Milestones such as the 2024 end-to-end test, with Starship surviving hypersonic re-entry and achieving a controlled splashdown, reflect a rapid iterate–test–fix rhythm that buyers translate into confidence about schedule and performance.

There’s also a talent dimension. Dual-site sprints attract and surface engineers who thrive under transparent metrics and time-boxed goals. University and industry observers made similar points during SpaceX’s Hyperloop Pod competitions; when teams ship to a spec, under a clock, you learn who can handle system integration under real constraints—the very skill set a high-cadence launch business needs. That culture carries into vendor relations: suppliers get clearer acceptance criteria, earlier DFM feedback, and faster change-control cycles, which in turn reduces downstream risk for payload customers.

The go-to-market logic is baked in. By allowing two architectures to mature in parallel, SpaceX could package reliability as an outcome (availability in critical windows, predictable turnaround) rather than as a hope. For satellite operators and in-house programmes like Starlink, that means tighter service-level commitments, better manifest discipline, and a clearer total cost of launch picture—factors that underpin multi-year agreements. Evidence from the commercial crew market and wider launch contracting shows that where credible alternatives exist, prices fall and service improves; internal competition is the same idea turned inward to compress time-to-capability.

For other space businesses, the lesson isn’t “duplicate everything.” It’s to mirror just enough—two lines, two software stacks, two materials sets—to test key uncertainties in parallel, then standardise the winners. Put shared dashboards on fault classes, rework hours and throughput so the contest is data-visible, not political. Publish conversion gates (when a branch becomes the standard), and tie incentives to fleet availability and incident reduction, not to pet designs. That converts rivalry into a governable operating system rather than chaos.

The result is fewer surprises and more credible promises to customers and financiers. SpaceX’s dual-site Starship sprint shows that structured internal rivalry—with disciplined knowledge sharing—can be a force multiplier on speed, cost and quality. In a market where cadence is king, that’s a durable edge.