In-Space Manufacturing: What’s Viable First—and How to Price It

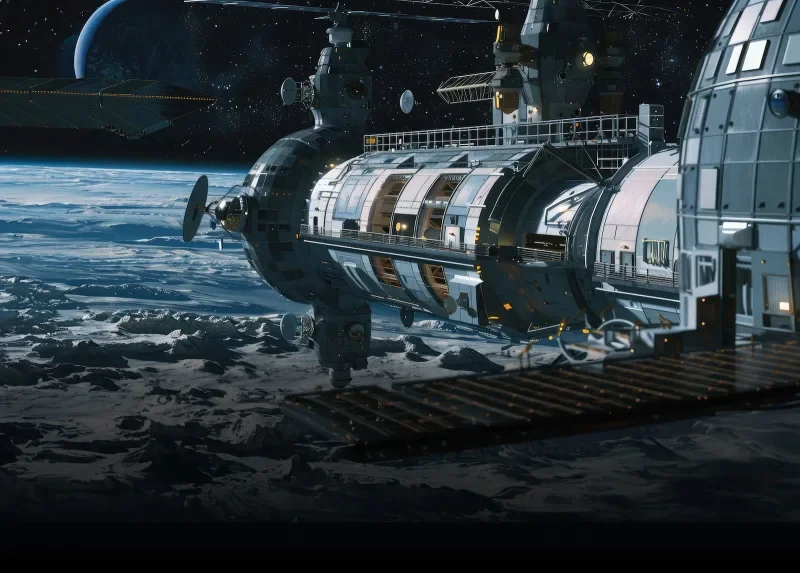

Concept art of an automated space factory in orbit.

Credit: Sania/Adobe Stock

Selecting early products and the unit economics that matter

In-space manufacturing promises materials and processes impossible—or uneconomic—on Earth due to gravity, convection and contamination. Early candidates follow a simple rule: high value-to-mass, strong performance premium, and low process complexity. Examples include specialty optical fibres, protein crystallisation for drug discovery, ultra-pure semiconductors, and precision alloys or foams. The nearer-term commercial winners are likely those that can be made autonomously, in small batches, and either returned to Earth with minimal handling or used in situ to extend spacecraft life or activities in space.

Unit economics hinge on a few levers: cost to orbit and return, facility utilisation (duty cycle), yield variability, power/thermal budgets, and price elasticity for the improved material. Reusability and high-cadence logistics compress the logistics component of cost of goods sold; on-orbit automation and process control stabilise yields; and vertical integration across launch, hosting and return reduces interfaces and delays. Where return-to-Earth economics are marginal, “manufacture-for-orbit” can close sooner—think radiation-hardened components, large-format structures, or fluids processed for on-orbit customers.

Investors should expect long gestation but non-linear risk retirement: once a particular process proves stable across multiple cycles, scale can come in modular increments with improving yields and capex efficiency. That is the Christensen pattern again—start “narrow and deep,” learn fast with early adopters, then generalise.

Commercial Takeaways

Founders should prioritise one product with a clear performance premium and a customer willing to validate specs and purchase off-take; design facilities for autonomous operation, remote QA/QC, and safe abort/return. Investors should diligence process stability (run-to-run control), logistics partnerships for frequent return, and margin sensitivity to launch/return pricing. Enterprise buyers should co-develop specs and secure options to lock supply once performance is verified. Policy-makers should procure services (hosting, sample return) and streamline customs/export workflows for space-made goods rather than layering prescriptive rules that slow cadence.