Synthetic Data & Digital Twins: Closing the Sim-to-Real Gap

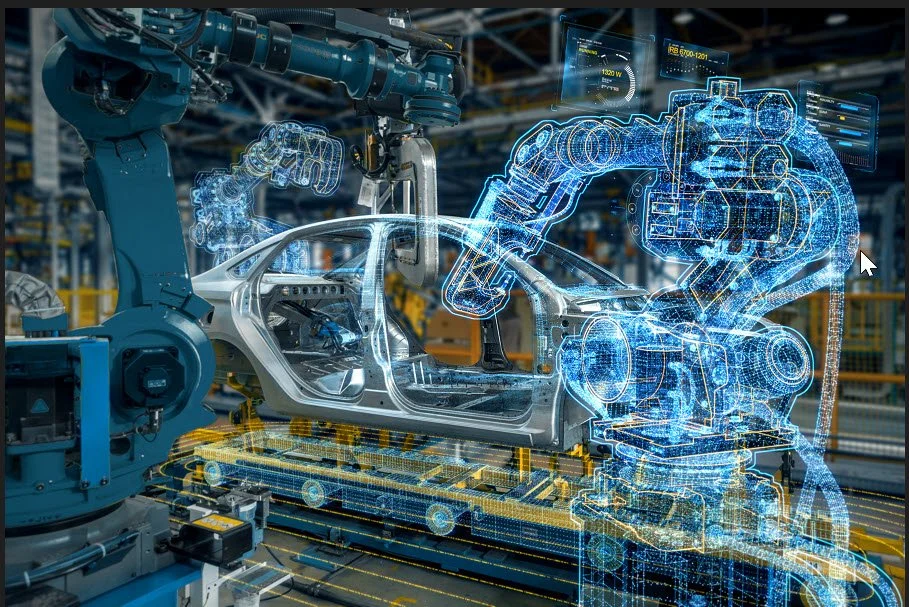

Delmia (a Dassault brand) used a robotics virtual twin (RVT) as a digital model that is connected to a physical robot or process that it represents.

Credit: Dassault Systèmes

Why simulation is becoming a revenue enabler, not merely an engineering tool

Simulation has moved from backroom tool to commercial enabler. If perception models learn faster on synthetic data, and if programming and validation happen first in a high-fidelity twin, time-to-value and commissioning risk both shrink. Buyers are starting to treat simulation capability as part of the product.

The landscape spans open platforms and OEM suites. NVIDIA’s Isaac Sim provides physically based environments, domain randomisation and synthetic data pipelines (Replicator) for training and testing, while Gazebo/Ignition remains a widely used open-source simulator with ROS 2 bridges. On the OEM side, ABB’s RobotStudio and Siemens’ Tecnomatix Process Simulate offer offline programming and digital-twin environments that map closely to their ecosystems. The mix is healthy: one size will not fit all, but the direction of travel—more fidelity, easier data generation, tighter integration with deployment—is clear.

The commercial angle is straightforward. If you can demonstrate that new SKUs, EOATs or layouts are validated in simulation, with collision checks and timing analysis, buyers feel less like guinea pigs. If your perception stack arrives with synthetic-data-trained models plus evidence of domain randomisation, buyers expect fewer on-site tuning cycles. That accelerates revenue for both parties. It also creates new service lines—simulation-as-a-service for customers who want to test their own variants before committing to hardware.

GTM rationale is evolving from “we have a simulator” to “simulation is how we guarantee predictability.” Vendors that export validation artefacts—videos, timing traces, logs—win trust in committees where operations and safety sit alongside finance. Expect more RFPs to ask not only for on-site FAT/SAT plans but for evidence of offline testing in recognised tools.

Standards won’t write your simulator, but they will shape your evidence. If your simulation artefacts align with the same safety standards used at commissioning (ISO 10218/TS 15066), you reduce review friction. When the unit lands, fewer people are surprised—and that is the commercial definition of success.