Warehouse Intelligence: Quantum Optimisation for AMR Fleets and ASRS Orchestration

Many robotic vendors currently have varying degrees of Artificial Intelligence (AI) and Machine Learning (ML) incorporated into their fleet management software, but haven’t reached a level of quantum optimisation yet.

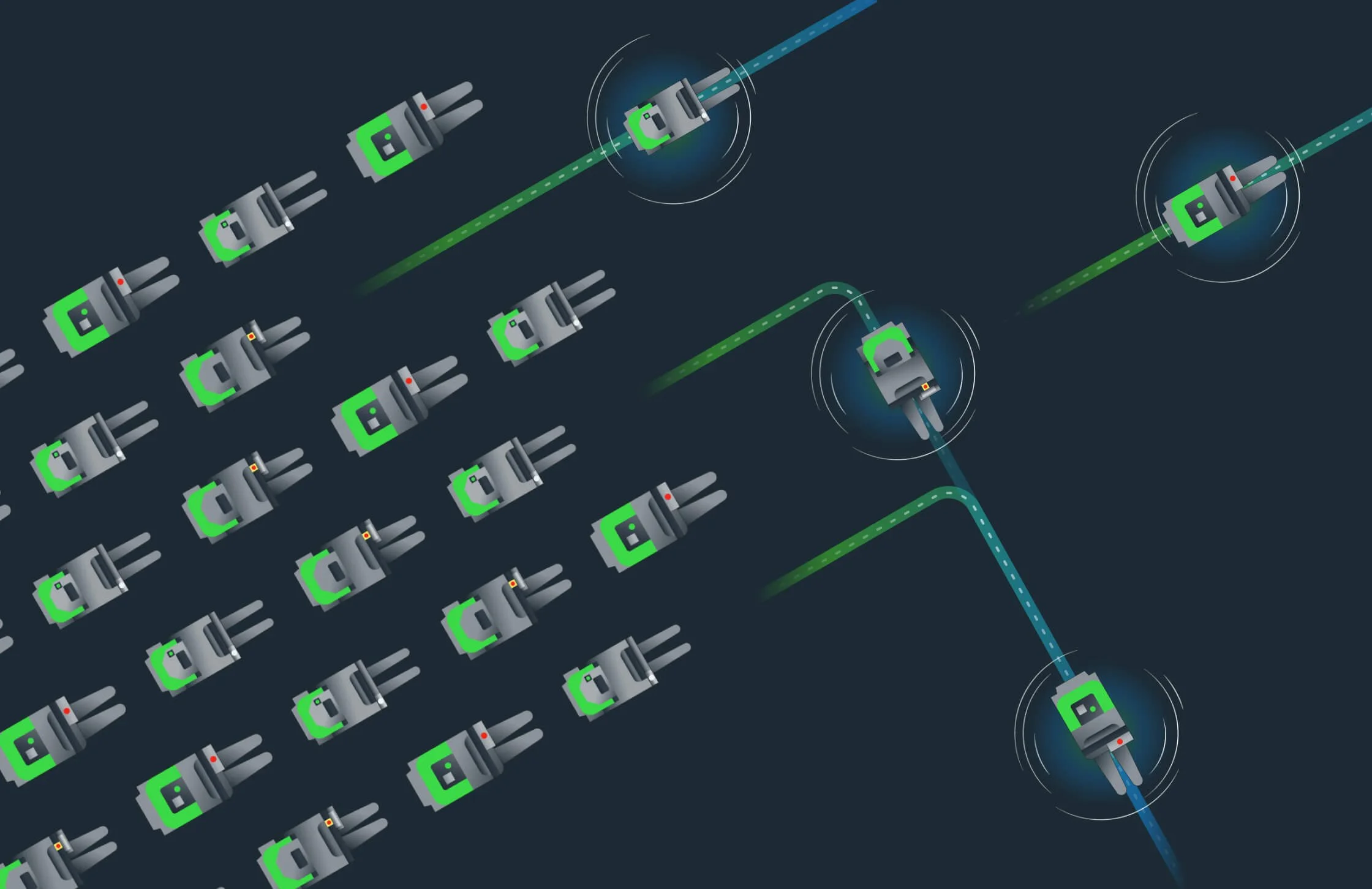

Credit: Vecna Robotics

Scheduling, routing and slotting when robots, aisles and lifts all compete

Modern fulfilment centres are crowded with automation: AMRs/AGVs, tuggers, pallet movers, mobile manipulators on some sites, and ASRS shuttles or cranes. The orchestration problem—missions, routes, traffic rules, lift/elevator access, battery cycles, slotting and waves—explodes combinatorially. Quantum optimisation is being tested as a co-solver inside warehouse execution systems (WES), especially for tough instances of routing, task assignment and slotting that stress classical heuristics.

Evidence is emerging. Logistics studies using annealers and hybrid methods show promise for vehicle routing and AGV scheduling mapped to QUBO formulations; results often read as “quantum proposes good candidates quickly, classical polishes.” Industrial case studies and peer-reviewed work point to real-world routing improvements at meaningful scales, while cautioning that integration—not algorithms alone—determines outcomes.

Operational questions are concrete. Can the solver respect safety envelopes and traffic rules? Does it integrate with the fleet manager, WMS and ASRS controllers? How does it treat charge/swap windows and elevator/door constraints? And can the output be audited when something goes wrong on the floor? Buyers don’t care about abstract speed-ups; they want lower congestion, tighter makespan and fewer human interventions—measured against today’s KPIs.

The commercial shape therefore looks like an API attached to the WMS/WES, not a standalone science project. Providers who offer digital-twin sandboxes for A/B testing on historical data, then support controlled cut-overs with roll-back, are easier to buy. Publishing guardrails (latency budgets, maximum problem sizes) and explaining graceful degradation if a QPU is unavailable reduces operational fear. Partnerships with AMR and ASRS suppliers on interface kits—traffic control, lift scheduling, battery/charging windows—accelerate deployment.

A sensible adoption path starts with one site and one painful orchestration knot (e.g., cross-dock peaks), demonstrates reliability in the twin, and expands once site teams trust the solver. The headline isn’t “quantum runs your warehouse”; it’s “your warehouse runs more smoothly under stress.”